Previous slide

Next slide

Monel Alloy 404

Shapes:

Plate & Sheet,Coil,Strip,Bar,Pipe & Tube,Wire & Mesh

Grades:

- ASTM: B[Relevant ASTM grade number for 404] / UNS N[Corresponding UNS number]

- ASME: SB[ASME grade number] / N[UNS number]

- JIS: G[JIS standard code] / NW [JIS-designated number]

- AISI: [Specific AISI grade]

- EN: [Applicable EN standard number] / [EN alloy code for 404]

Huaxiao Metal is a highly respected Monel 404 supplier. We are committed to providing a comprehensive range of top-notch Monel 404 products. Our inventory covers all the major grades, whether it’s the ones compliant with ASTM, ASME, JIS, AISI, or EN standards. No matter if you’re on the hunt for Monel 404 plates for building chemical-resistant tanks, pipes for industrial plumbing, or wire for electrical wiring in corrosive environments, we’ve got you covered.

Monel Alloy 404 Shapes

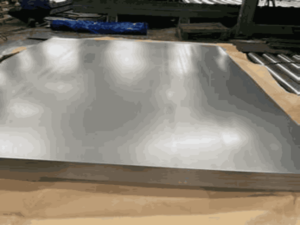

Monel 404 Plate & Sheet

Monel 404 alloys are notable for their unique set of properties. They possess reliable corrosion resistance, which is particularly useful in a range of chemical environments. Their composition endows them with the ability to withstand the corrosive effects of various chemicals, making them valuable in industries such as specialty chemical processing, pharmaceutical manufacturing, and certain segments of electronics production. Alongside corrosion resistance, Monel 404 also has decent mechanical properties, enabling it to be formed, machined, and used in applications that require structural integrity.

Dimensions:

Thickness: 0.05 mm – 80 mm. This wide thickness range allows for flexibility in design, with thinner sheets suitable for more delicate, precision applications, like in microelectronics, and thicker plates for heavier-duty, load-bearing structures in industrial equipment.

Width: 20 mm – 400 mm, along with custom widths available upon request. Whether you’re working on a small-scale DIY project or a large industrial installation, we can accommodate your specific width needs.

Length: 1000 mm, 1800 mm, 2800 mm, and custom lengths negotiable. This ensures that you can get the exact length required for your project, minimizing waste and optimizing cost.

Thickness: 0.05 mm – 80 mm. This wide thickness range allows for flexibility in design, with thinner sheets suitable for more delicate, precision applications, like in microelectronics, and thicker plates for heavier-duty, load-bearing structures in industrial equipment.

Width: 20 mm – 400 mm, along with custom widths available upon request. Whether you’re working on a small-scale DIY project or a large industrial installation, we can accommodate your specific width needs.

Length: 1000 mm, 1800 mm, 2800 mm, and custom lengths negotiable. This ensures that you can get the exact length required for your project, minimizing waste and optimizing cost.

For pricing, availability, and custom Monel 404 Plate & Sheet sizes, please contact us!

We are a trusted Monel 404 supplier and wholesale Monel 404 provider. Whether you need standard products or have unique requirements for sizes, our items undergo rigorous quality inspections to make sure they fulfill your industrial requirements.

We are a trusted Monel 404 supplier and wholesale Monel 404 provider. Whether you need standard products or have unique requirements for sizes, our items undergo rigorous quality inspections to make sure they fulfill your industrial requirements.

Monel 404 Coil

Monel 404 coils are highly regarded in a variety of industries, thanks to their distinctive characteristics. This alloy is famed for its notable corrosion resistance, capably fending off a range of corrosive substances commonly encountered in industrial processes. It shows reliable performance against certain acids, reactive chemicals, and even mildly corrosive gases, which makes it an excellent choice for sectors such as specialty chemical production, pharmaceutical R&D, and electronics manufacturing where material integrity is crucial. Besides, Monel 404 maintains good mechanical properties over an acceptable temperature span, enabling it to function well in both cooler and moderately warm operating conditions.

In industrial fields like advanced chemical laboratories, biopharmaceutical plants, and high-tech electronics factories, Monel 404 coils play a vital role. They are frequently utilized in custom heat exchangers, precision tubing setups, and sensitive sensor components, where consistent and dependable performance is non-negotiable.

Dimensions:

- Thickness: Ranging from 0.03 mm to 30 mm. The thinner coils within this range are perfect for intricate, high-precision tasks that demand fine-tuned control, while the thicker ones offer the necessary robustness for applications requiring more structural strength.

- Width: Spanning from 50 mm to 1200 mm, and we also provide custom widths to suit the unique demands of each project. This flexibility ensures that whether your project is small-scale or large-scale, we can meet your width requirements precisely.

- Length: Beginning at 300 mm, with custom lengths negotiable. This allows for tailoring the coil length to the exact installation needs, reducing waste and optimizing cost-effectiveness.

For pricing, availability, and custom Monel 404 Coil sizes, please contact us! We are a dependable Monel 404 supplier and a wholesale provider of top-quality Monel 404 products. Whether you require standard coils for regular production runs or have special demands for size, our products are subject to strict quality inspections to ensure they meet all your industrial requirements. Contact us without delay.

Monel 404 Strip

Monel 404 strips are in high demand across multiple industrial sectors, owing to their exceptional properties. This alloy is renowned for its reliable corrosion resistance, which is especially valuable when dealing with certain chemicals and reducing environments. It can withstand the corrosive effects of various acidic and basic substances, safeguarding components in industries like specialty chemical manufacturing, pharmaceutical production, and electronics assembly. Alongside corrosion resistance, Monel 404 also offers good mechanical strength, allowing it to be easily formed, bent, or cut into the precise shapes required for different applications.

In industrial applications, Monel 404 strips serve a multitude of purposes. They are often used in the production of electrical connectors, where corrosion-free contacts are essential for reliable electrical conductivity. In addition, these strips can be found in corrosion-resistant linings, providing a protective barrier within chemical reactors or storage tanks.

Dimensions:

- Thickness: Monel 404 strips typically range from 0.01 mm to 5 mm. Thinner strips are ideal for applications demanding high precision, such as in microelectronics or sensor manufacturing, while thicker strips are more suitable for applications that require greater mechanical strength, like spring production.

- Width: Available widths span from 10 mm to 300 mm, and we also offer custom widths to meet the exact requirements of your project. This flexibility ensures that the strips can be integrated seamlessly into a wide variety of designs, regardless of size constraints.

- Length: Strips can be supplied in lengths starting from 500 mm, with custom lengths negotiable. This allows you to obtain the precise amount of material needed, minimizing waste and optimizing cost.

For pricing, availability, and any custom requests regarding Monel 404 strips, please contact us. We are a trusted Monel 404 supplier, committed to providing high-quality products. Our items undergo strict quality inspections, from the selection of raw materials to the final packaging, ensuring that they meet your industrial needs. Reach out to us at your earliest convenience.

Monel 404 Pipe & Tube

Monel 404 pipes and tubes have gained significant popularity in a host of industries, thanks to their remarkable characteristics. This alloy is celebrated for its excellent corrosion resistance, which is especially pronounced in environments containing specific chemicals and reducing agents. It can tenaciously withstand the corrosive impacts of various acidic, basic, and reactive chemical substances, thus ensuring the durability and reliable operation of equipment in sectors like specialty chemical manufacturing, pharmaceutical production, and electronics applications. Additionally, Monel 404 retains its mechanical strength over a wide temperature range, making it suitable for use in both cooler and relatively warm operating conditions.

In the specialty chemical industry, Monel 404 pipes and tubes are crucial for transporting highly reactive and corrosive chemicals, protecting the integrity of the transfer systems. For pharmaceutical plants, they act as reliable conduits for intermediate compounds, preventing any contamination that could affect product quality. In electronics manufacturing, they can be used in coolant or gas delivery systems where corrosion resistance and material stability are essential.

Dimensions:

- Outer Diameter: Spanning from 3 mm to 400 mm, this broad range of sizes caters to diverse flow requirements. Smaller diameters are perfect for precision fluid handling in laboratory-scale setups, while larger diameters can manage higher volume flows in industrial-scale operations.

- Thickness: Ranges from 0.3 mm to 30 mm. Thinner walls are cost-effective for low-pressure applications where corrosion resistance is still needed, while thicker walls provide the necessary strength to withstand higher pressures, such as in high-pressure chemical reactions.

- Length: Standard lengths include 1500 mm, 3000 mm, and 6000 mm, and we also offer custom lengths. This flexibility allows for seamless integration into any project layout, regardless of its specific dimensions.

For details regarding pricing, availability, and custom Monel 404 Pipe & Tube sizes, please contact us. As a trusted Monel 404 supplier and wholesale provider, we are committed to ensuring that our products meet the strictest quality standards. Our items go through rigorous quality inspections,

Monel 404 Wire & Mesh

Monel 404 wire and mesh products are highly sought-after in various industries, owing to their unique set of properties. This alloy is renowned for its notable corrosion resistance, especially when exposed to certain chemicals and reducing environments. It can effectively withstand the corrosive effects of various acidic, alkaline, and reactive substances, which makes it invaluable in sectors such as specialty chemical manufacturing, pharmaceutical production, and electronics applications. Alongside corrosion resistance, Monel 404 also demonstrates good mechanical strength, allowing it to maintain its integrity during handling, weaving, and long-term use.

In industrial applications, Monel 404 wire serves multiple purposes. It is often used for creating electrical conductors in environments where corrosion can quickly degrade other metals. The mesh, on the other hand, finds extensive use in filtration systems. Here, it can selectively filter out particles while enduring exposure to corrosive fluids, ensuring the purity of the filtered substances. Additionally, in electronics, it can be utilized for shielding sensitive components from electromagnetic interference, all while protecting against corrosive agents.

Dimensions:

- Wire Diameter: Monel 404 wire diameters typically range from 0.03 mm to 5 mm. Finer diameters are ideal for intricate electrical wiring and delicate sensor applications, where precision is key. Larger diameters are more suitable for applications that demand greater mechanical strength, like in robust electrical connections.

- Mesh Size: For the mesh, aperture sizes vary widely. From very fine meshes with apertures as small as 0.05 mm, perfect for filtering out minute particles, to coarser meshes with apertures up to 10 mm, which are useful for applications such as debris screening in industrial pipelines.

- Sheet Size (for Mesh): Mesh sheets usually come in widths from 50 mm to 1500 mm and lengths from 300 mm to 3000 mm, with custom sizes available upon request.

For pricing, availability, and any custom requests related to Monel 404 wire and mesh, please contact us. We are a reliable Monel 404 supplier, dedicated to providing high-quality products. Our items undergo strict quality inspections, from raw material sourcing to the final packaging, ensuring they meet all your industrial needs.

Monel 404 Bar

Monel 404 bars are prized assets in a wide array of industries, thanks to their outstanding blend of properties. This nickel-copper alloy is highly regarded for its excellent corrosion resistance, which truly shines in environments rife with specific chemicals and reducing agents. It can stoutly withstand the corrosive onslaught of various acidic, basic, and gaseous substances, making it an ideal choice for sectors like specialty chemical processing, pharmaceutical manufacturing, and electronics production where material integrity is non-negotiable. Besides corrosion resistance, Monel 404 bars also possess good mechanical strength, enabling them to be machined, formed, and incorporated into complex structures with relative ease.

In industrial applications, Monel 404 bars serve as essential building blocks. They are frequently used in the fabrication of shafts, valves, and fasteners. In chemical plants, shafts made from Monel 404 bars can power mixers and agitators, enduring the corrosive chemicals in the reaction vessels. Valves crafted from these bars ensure leak-free operation when handling corrosive fluids, and fasteners maintain their integrity, holding structures together even in harsh chemical-laden atmospheres.

Dimensions:

- Diameter: Monel 404 bars come in a diverse range of diameters. Starting from as small as 3 mm, which is perfect for creating delicate, precision components such as pins in small-scale electronic devices, up to 200 mm for larger, load-bearing parts like heavy-duty shafts in industrial machinery.

- Length: Available lengths typically span from 1 meter to 6 meters, and custom lengths can be arranged. This flexibility means that you can obtain precisely the amount of material required for your project, minimizing waste and optimizing cost.

For pricing, availability, and any custom requests regarding Monel 404 bars, please contact us. We are a trusted Monel 404 supplier, committed to delivering high-quality products. Our bars go through rigorous quality inspections, from the procurement of raw materials to the final dispatch, ensuring they meet your industrial requirements.

Monel Alloy 404 Chemical Composition

Monel 404 is a specialized nickel-copper alloy that offers distinct properties, making it suitable for particular industrial applications. It has notable corrosion resistance, which is especially effective in environments containing certain reducing agents, acidic substances, and specific chemicals. This makes it a favored choice in industries such as specialty chemical production, pharmaceutical processing, and some segments of electronics manufacturing, where safeguarding against corrosion is of utmost importance, along with having adequate mechanical strength.

The typical chemical composition of Monel 404 is as follows:

Chemical Composition of Monel 404:

Chemical Composition of Monel 404:

| Element | Composition (wt.%) |

|---|---|

| Nickel (Ni) | [Typically a significant proportion, being the base element] |

| Copper (Cu) | [A major secondary element, working in harmony with nickel] |

| Iron (Fe) | [Present in a small amount, influencing the alloy’s physical and chemical properties] |

| Manganese (Mn) | [Minor quantity, contributing to alloy workability and stability] |

| Carbon (C) | ≤ 0.3 (Helps regulate hardness and ductility) |

| Silicon (Si) | ≤ 0.5 (Affects casting properties and alloy fluidity) |

| Sulfur (S) | ≤ 0.024 (Low levels to prevent negative impacts on corrosion resistance) |

| Phosphorus (P) | ≤ 0.02 (Ensures good alloy integrity and minimal corrosion promotion) |

While exact percentages may vary based on specific manufacturing requirements and standards, this general composition equips Monel 404 with the characteristics that set it apart from other alloys in the Monel series, enabling it to perform well in its niche industrial applications.

Data Sheet

Physical Properties

| Property | Value |

|---|---|

| Density | Approximately 8.88 g/cm³ 0.321 lb/in³ |

| Melting Range | [Available data shows] around 2335 °F – 2400 °F 1280 °C – 1315 °C |

| Modulus of Elasticity Tension | Roughly 26 x 10³ ksi 179 x 10³ Mpa |

| Modulus of Elasticity Compression | Approximately 26 x 10³ ksi 179 x 10³ Mpa |

| Modulus of Elasticity Torsion | Around 9.2 x 10³ ksi |

| Poisson’s Ratio | Typically in the range of 0.3 – 0.32 (close to that of related Monel alloys) |

| Curie Temperature | [Data may vary, but generally] -180 – (-120) °F -115 – (-85) °C |

| Thermal Conductivity | Approximately 21.0 W/m·K 13.3 Btu/hr/ft²/ft/°F |

| Specific Heat | [Approximate value] 0.42 Btu/lb·°F |

| Coefficient of Thermal Expansion (25 – 100°C) | Around 13.5 x 10⁻⁶ /°C |

| Electrical Resistivity | Approximately 290 – 300 µΩ·cm |

Mechanical Properties

| Form and Condition | Tensile Strength | Yield Strength (0.2% Offset) | Elongation, % | Hardness |

|---|---|---|---|---|

| Annealed | 50 – 65 ksi 345 – 448 MPa | 25 – 35 ksi 172 – 241 MPa | 30 – 40 | Rockwell B 60 – 80 |

| Cold-Worked (Drawn) | 70 – 90 ksi 483 – 621 MPa | 35 – 55 ksi 241 – 379 MPa | 20 – 30 | Rockwell B 80 – 100 |

| Hot-Finished | 60 – 80 ksi 414 – 552 MPa | 30 – 45 ksi 207 – 310 MPa | 25 – 35 | Rockwell B 70 – 90 |

| Welded (As-welded, Annealed) | 45 – 60 ksi 310 – 414 MPa | 20 – 35 ksi 138 – 241 MPa | 20 – 30 | Rockwell B 55 – 75 |

| Stress-Relieved | 65 – 90 ksi 448 – 621 MPa | 30 – 50 ksi 207 – 345 MPa | 25 – 35 |

Monel 404 Introduction

Overview

Huaxiao Metal, a prominent name in the metal supply industry, serves as a reliable supplier for both Monel 400 and Monel 404. Monel 404 (UNS [specific UNS number]), like its cousin Monel 400, is a nickel – copper alloy with unique properties. It is highly sought-after for specialized industrial applications, especially those involving certain corrosive chemicals and reducing environments.

When comparing Monel 404 with alloys such as Inconel 625, Monel 404 stands out in its ability to resist specific chemicals prevalent in specialty chemical manufacturing and pharmaceutical production. While Inconel 625 excels in extreme high – temperature oxidation resistance, Monel 404 offers a more targeted solution for applications where corrosion from particular acids, bases, or reactive gases needs to be combated. And when pitting 405 Monel against 404, differences in their chemical compositions lead to variations in properties like corrosion resistance and hardness.

What is Monel 404?

Monel 404 is a nickel – copper alloy. Its composition, detailed further in the “monel 404 composition” section, gives it distinct properties. It’s designed to perform well in environments where other alloys might succumb to corrosion, making it a staple in industries such as electronics, chemical processing, and pharmaceutical manufacturing.

Who sells Monel?

Huaxiao Metal is a leading supplier of Monel alloys, including Monel 404. We offer a comprehensive range of Monel 404 products, from rods like “monel 404 rod B” to wires, sheets, and tubes. Our inventory covers standard sizes, and we also accept custom orders to meet the diverse requirements of our customers.

Is Monel better than Inconel?

It depends on the application. Monel, including Monel 404, has an edge when it comes to corrosion resistance in specific chemical environments, like those with certain acids or reducing agents. Inconel, on the other hand, is unrivaled in extreme high – temperature oxidation – resistant applications. So, neither is objectively “better”; rather, they are optimized for different industrial niches.

Monel 404 Composition

The monel 404 chemical composition mainly consists of nickel as the principal element, along with copper. Trace amounts of other elements such as iron, manganese, and carbon are also present. These elements work in harmony to confer its characteristic properties. The precise monel 404 composition dictates aspects like its corrosion resistance, mechanical strength, and even its astm monel metal 404 elastic modulus.

Monel 404 Properties

- Hardness: Monel 404 has a specific hardness range. This hardness makes it suitable for applications where abrasion resistance and shape retention under mechanical stress are necessary, like in valve components.

- Electrical Conductivity: It possesses a moderate level of electrical conductivity, enabling its use in applications where both electrical conduction and corrosion resistance are required, for example, in some electrical connectors in industrial settings.

- Elastic Modulus: The astm monel metal 404 elastic modulus determines how the alloy deforms under stress, which is crucial for components that experience dynamic loads.

Common Monel 404 Products

- Monel 404 Rod B: These rods are often used in machining operations to produce custom parts. Their solid form and the properties of Monel 404 make them ideal for creating components that require strength and corrosion resistance.

- Monel 404 Wire: Monel 404 wire is highly valued in applications like electrical wiring in corrosive environments or in the creation of fine – mesh screens for filtration purposes, leveraging its electrical and anti – corrosion characteristics.

As a wholesale Monel 404 supplier, Huaxiao Metal’s strict quality control procedures ensure that every product, whether it’s a simple wire or a complex tube assembly, meets the highest standards. Whether you’re involved in large – scale industrial projects or small, specialized applications, contact us right away to learn more about Monel 404 pricing, availability。

Monel 404 Applications

Pharmaceutical Manufacturing

Chemical Processing

Nuclear Power Industry

Marine and Offshore Applications

FAQ

Monel 404 and Monel 405 are both nickel-copper alloys, but they have some differences:

- Composition: Their exact elemental proportions vary. These differences in the alloying elements lead to distinct physical and chemical properties. Even small changes in the amounts of elements like iron, manganese, or carbon can impact performance.

- Corrosion Resistance: Monel 404 has better resistance in certain reducing chemical environments, which makes it a top choice for specialty chemical and pharmaceutical applications. Monel 405, on the other hand, may be more suitable for applications where a different set of corrosive agents or conditions are present.

- Hardness: There’s a disparity in hardness levels. This means they’re better suited for different mechanical applications; for example, a harder alloy might be better for wear-resistant parts, while a softer one can be more easily machined.

- Application: Monel 404 is often found in electronics, pharmaceutical production, and specialty chemical processing. Monel 405 has applications more focused on scenarios where its unique corrosion resistance and mechanical properties are a better match, like some specific oil and gas downstream operations.

Whether Monel is better than Inconel depends on the application. Monel, with alloys like Monel 400, excels in corrosion resistance against seawater, hydrofluoric acid, and alkalis, making it great for marine and chemical processing. Inconel, on the other hand, is designed for high-temperature, oxidation-resistant scenarios such as jet engine parts. So, there’s no absolute “better”; it’s about matching the alloy to the job requirements.

More Monel Grades

Monel Alloy 400

January 2, 2025

No Comments

Previous slide Next slide Monel Alloy 400 Shapes: Plate & Sheet, Coil, Strip, Bar, Pipe & Tube, Wire & Mesh Grades: ASTM: B127 / UNS

Monel Alloy 404

December 18, 2024

No Comments

Previous slide Next slide Monel Alloy 404 Shapes: Plate & Sheet,Coil,Strip,Bar,Pipe & Tube,Wire & Mesh Grades: ASTM: B[Relevant ASTM grade number for 404] / UNS

Monel Alloy 401

December 18, 2024

No Comments

Previous slide Next slide Monel Alloy 401 Shapes: Plate & Sheet,Coil,Strip,Bar,Pipe & Tube,Wire & Mesh Grades: ASTM: [Relevant ASTM grade code for Monel 401] /