Previous slide

Next slide

Monel Alloy 401

Shapes:

Plate & Sheet,Coil,Strip,Bar,Pipe & Tube,Wire & Mesh

Grades:

ASTM: [Relevant ASTM grade code for Monel 401] / UNS N04401

ASME: [ASME equivalent grade] / N04401

JIS: [JIS specification code] / [JIS designator for 401]

AISI: [AISI relevant code]

EN: [Applicable EN standard number] / [EN alloy code for 401]

ASME: [ASME equivalent grade] / N04401

JIS: [JIS specification code] / [JIS designator for 401]

AISI: [AISI relevant code]

EN: [Applicable EN standard number] / [EN alloy code for 401]

Huaxiao Metal stands out as a premier Monel 401 alloy supplier. We are committed to delivering an expansive range of top-notch Monel 401 products. With grades like ASTM [grade number] and UNS N04401 in our inventory, no matter if you’re in search of Monel 401 bars for mechanical assemblies, pipes for chemical pipelines, sheets for cladding, or wire for electrical grounding, we have the perfect solution for you.

Monel Alloy 401 Shapes

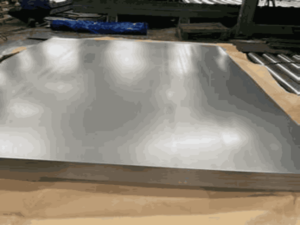

Monel 401 Plate & Sheet

Monel 401 alloys are highly prized for their unique set of properties. They possess remarkable resistance to a variety of corrosive media, making them stand out even in extremely challenging chemical conditions. In addition to good general corrosion resistance, Monel 401 shows particular resilience in reducing environments, which is crucial for applications in certain chemical processing plants. It also has decent mechanical strength, enabling it to withstand mechanical stresses during fabrication and in-service use. This makes Monel 401 much sought-after in industries like specialty chemical production, pharmaceutical manufacturing, and some segments of the electronics industry.

Dimensions:

- Thickness: 0.05 mm – 80 mm, providing options for both thin, precision components and thicker, more structurally demanding parts.

- Width: 20 mm – 400 mm, 600 mm, 800 mm, 1000 mm, 1200 mm, 1400 mm, 1600 mm, 2000 mm, with custom widths also available to fit your specific project requirements.

- Length: 1000 mm, 1800 mm, 2200 mm, 3000 mm, 4000 mm, 5500 mm, 9000 mm, along with custom lengths upon request.

We are a leading Monel 401 alloy supplier. As a trusted wholesale provider of Monel 401 products, we ensure that every batch of our Monel 401 Plate & Sheet meets the highest quality standards. Whether you’re interested in leveraging the properties of this alloy for a new product development, or you have a long-term industrial project that demands consistent supply of Monel 401, we’ve got you covered. For pricing details, product availability, and any custom size requests for Monel 401 Plate & Sheet, don’t hesitate to contact us right away.

Monel 401 Coil

Monel 401 coils are highly sought-after in a diverse array of industries, owing to their distinctive characteristics. This alloy is renowned for its excellent corrosion resistance, particularly excelling in reducing environments. It can hold up well against a host of aggressive chemicals, acidic substances, and certain reactive gases, which makes it indispensable in sectors such as specialty chemical manufacturing, pharmaceutical production, and high-precision electronics assembly. Besides its corrosion-fighting capabilities, Monel 401 also demonstrates good mechanical strength, allowing it to endure the rigors of shaping, forming, and long-term operation.

Dimensions:

- Thickness: Ranging from 0.03 mm to 30 mm. The thinner coils within this range are ideal for intricate, high-precision tasks, while the thicker ones can be used in applications that require more structural robustness.

- Width: Spanning from 50 mm to 1200 mm. Additionally, we offer custom widths to cater to the unique demands of each project.

- Length: Beginning at 300 mm, and custom lengths are available upon request, ensuring a perfect fit for any installation.

For pricing, availability, and custom Monel 401 Coil sizes, please contact us! We are a leading Monel 401 alloy supplier and a trusted wholesale provider of Monel 401 products. Whether you require standard items or have specific size requirements, our products are put through rigorous quality checks to make certain they fulfill your industrial requirements. Contact us right away.

Monel 401 Strip

Monel 401 strips are prized assets across multiple industries, thanks to their exceptional attributes. This alloy offers remarkable corrosion resistance, especially when exposed to reducing environments. It can fend off the corrosive onslaught of various chemicals, acidic solutions, and some industrial pollutants, making it a top choice in chemical processing, pharmaceutical R&D, and electronics manufacturing sectors where material purity and durability are of utmost importance. In addition to its anti-corrosion properties, Monel 401 has good mechanical properties, such as adequate tensile strength and formability, enabling it to be shaped into complex geometries with relative ease.

Dimensions:

- Thickness: The thickness of Monel 401 strips typically ranges from 0.01 mm to 5 mm. Thinner strips are perfect for applications demanding high precision, like microelectronics, while thicker ones can be used in more mechanically demanding scenarios, such as spring manufacturing.

- Width: Available widths span from 10 mm to 500 mm, and we also offer custom widths to meet the exact requirements of your project.

- Length: Strips can be supplied in lengths starting from 100 mm, with custom lengths negotiable, ensuring that you get the right amount of material for your specific installation.

Regarding the chemical composition of Monel 401, it mainly consists of nickel as the principal element, complemented by copper and trace amounts of other alloying elements including iron, manganese, and carbon. This unique composition endows the alloy with its characteristic properties, differentiating it from other alloys like 401 stainless steel. Understanding the monel metal composition is crucial for engineers and manufacturers as it directly impacts the strip’s performance in different applications.

We are a reliable Monel 401 alloy supplier. As a wholesale provider, we take pride in offering high-quality Monel 401 strips. Our products undergo strict quality inspections from raw material selection to the final packaging stage. Whether you need standard strips for regular production or have special demands for size or chemical composition, we’ve got you covered. For pricing, availability, and any custom requests, please contact us without delay.

Monel 401 Pipe & Tube

Monel 401 pipes and tubes are highly regarded in a wide spectrum of industries, owing to their outstanding properties. This alloy is celebrated for its excellent corrosion resistance, particularly in reducing environments. It can withstand the corrosive effects of a multitude of chemicals, including strong acids and certain reactive compounds, making it an ideal choice for applications in chemical processing plants, pharmaceutical manufacturing facilities, and electronics cleanrooms. Alongside its corrosion-resistant capabilities, Monel 401 also offers good mechanical strength, enabling it to bear internal and external pressures without deformation during operation.

Dimensions:

- Outer Diameter (OD): Ranges from 3 mm to 500 mm. Smaller diameters are perfect for applications that require precise fluid flow control, like in laboratory setups or microfluidic devices. Larger diameters can handle higher volume flows, suitable for industrial-scale chemical transfer.

- Wall Thickness: Varies from 0.5 mm to 50 mm. Thicker walls provide greater strength for high-pressure applications, while thinner walls are more cost-effective for low-pressure, non-demanding systems.

- Length: Standard lengths typically start at 1 meter, and we also offer custom lengths to fit the specific layout requirements of your project.

We are a leading Monel 401 alloy supplier. As a wholesale provider, we ensure that our Monel 401 pipes and tubes meet the highest quality standards. Our products go through rigorous quality inspections, from raw material sourcing to the final product delivery. Whether you need standard-sized pipes and tubes for routine operations or have special requirements for dimensions or performance, we’ve got you covered. For pricing, availability, and any custom requests, please contact us immediately.

Monel 401 Wire & Mesh

Monel 401 wire and mesh products are in high demand across a plethora of industries, thanks to their unique set of properties. This alloy is renowned for its exceptional corrosion resistance, especially in reducing environments. It can effectively combat the corrosive effects of various chemicals, acids, and certain industrial pollutants, making it an invaluable asset in chemical processing, pharmaceutical production, and electronics manufacturing. In addition to its anti-corrosion prowess, Monel 401 has decent mechanical strength, allowing it to maintain its integrity during handling, weaving, and long-term use.

Dimensions:

- Wire Diameter: For Monel 401 wire, diameters typically range from 0.05 mm to 5 mm. Finer diameters are suitable for intricate electrical wiring and delicate sensor applications, while larger diameters are used for more robust electrical connections or where mechanical strength is a priority.

- Mesh Size: In terms of mesh, the aperture sizes can vary widely. From very fine meshes with apertures as small as 0.1 mm, which are perfect for filtering out minute particles, to coarser meshes with apertures up to 10 mm, used for applications like debris screening in industrial pipelines.

- Sheet Size (for Mesh): Mesh sheets usually come in widths from 100 mm to 2000 mm and lengths from 500 mm to 5000 mm, with custom sizes available upon request.

We are a reliable Monel 401 alloy supplier. As a wholesale provider, we take pride in offering high-quality Monel 401 wire and mesh products. Our items undergo strict quality inspections, from the selection of raw materials to the final packaging. Whether you need standard products for regular production or have specific requirements for size, shape, or chemical properties, we’ve got you covered. For pricing, availability, and any custom requests, please contact us without delay.

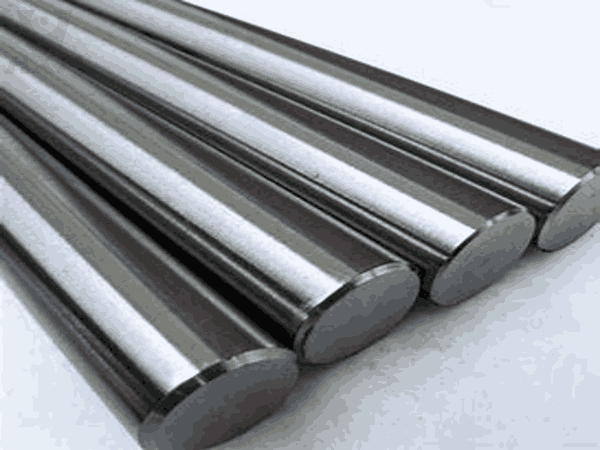

Monel 401 Bar

Monel 401 bars are highly favored in diverse industrial fields, owing to their remarkable characteristics. This alloy is celebrated for its outstanding corrosion resistance, particularly in reducing environments. It can tenaciously withstand the corrosive attacks of numerous aggressive chemicals, acids, and reactive gases, which makes it a staple in sectors like chemical processing, pharmaceutical manufacturing, and electronics industries. Alongside its corrosion-fighting capabilities, Monel 401 also showcases good mechanical strength, enabling it to be machined and formed into various components with ease.

Dimensions:

- Diameter: Monel 401 bars come in a wide range of diameters, starting from 3 mm for more delicate, precision components, and going up to 500 mm for larger, load-bearing parts. This broad spectrum allows for flexibility in design, whether you’re creating small, intricate parts or large-scale industrial fixtures.

- Length: Available lengths typically range from 1 meter to 6 meters, with custom lengths negotiable. This ensures that you can obtain the exact amount of material required for your specific project, minimizing waste and optimizing cost.

We are a leading Monel 401 alloy supplier. As a wholesale provider, we are committed to delivering high-quality Monel 401 bars. Our products go through stringent quality inspections, from the procurement of raw materials to the final product dispatch. Whether you need standard bars for routine production or have special requirements for diameter, length, or other properties, we’ve got you covered.

Monel Alloy 401 Chemical Composition

Monel 401 (UNS N04401) is a highly sought-after nickel-copper alloy, renowned for its unique set of properties that set it apart from other alloys in the Monel series. It exhibits outstanding corrosion resistance, particularly excelling in reducing environments. This makes it extremely valuable in industries dealing with aggressive chemicals, such as specialty chemical manufacturing, pharmaceutical production, and certain segments of the electronics industry where components are exposed to corrosive substances. Similar to its cousin Monel 400, it also maintains good mechanical properties, enabling it to withstand the rigors of machining, forming, and long-term operation in demanding industrial setups.

Below is the typical chemical composition of Monel 401:

Chemical Composition of Monel 401 (UNS N04401):

Chemical Composition of Monel 401 (UNS N04401):

| Element | Composition (wt.%) |

|---|---|

| Nickel (Ni) | [Principal amount, typically high as it’s the base element] |

| Copper (Cu) | [Significant percentage, working in tandem with nickel] |

| Iron (Fe) | [Minor quantity, contributing to certain physical properties] |

| Manganese (Mn) | [Small amount, influencing alloy’s behavior during processing] |

| Carbon (C) | ≤ 0.3 (Controlling factors like hardness and ductility at appropriate levels) |

| Silicon (Si) | ≤ 0.5 (Affecting the alloy’s fluidity during casting, among other things) |

| Sulfur (S) | ≤ 0.024 (Minimal presence to avoid negative impacts on corrosion resistance) |

| Phosphorus (P) | ≤ 0.02 (Keeps the alloy’s integrity intact and affects corrosion behavior marginally) |

Data Sheet

Physical Properties

| Property | Metric | Imperial |

|---|---|---|

| Density | 8.88 g/cm³ | 0.321 lb/in³ |

| Melting Range | 2335 – 2400 °F 1280 – 1315 °C | |

| Modulus of Elasticity Tension | 26 x 10³ ksi 179 x 10³ Mpa | |

| Thermal Conductivity (at 70 °F) | 21.0 W/m·K 13.3 Btu/hr/ft²/ft/°F | |

| Mean Coefficient of Thermal Expansion 70 – 200 °F 70 – 500 °F 70 – 1000 °F | 7.6 x 10⁻⁶ /°F 8.5 x 10⁻⁶ /°F 9.2 x 10⁻⁶ /°F | |

| Electrical Resistivity (at 70 °F) | 294 µΩ·m | 1.16 x 10⁻⁶ Ω·in |

| Poisson’s Ratio | Approximately 0.3 – 0.32 | – |

| Specific Heat Capacity (at room temperature) | 420 J/(kg·K) | 0.10 Btu/(lb·°F) |

| Tensile Strength (Annealed) | 50 – 65 ksi 345 – 448 MPa | – |

| Yield Strength (0.2% Offset) (Annealed) | 25 – 35 ksi 172 – 241 MPa | – |

| Elongation (Annealed) | 30 – 40% | – |

| Hardness (Annealed, Rockwell B) | 60 – 80 | – |

Mechanical Properties

Monel 401 (UNS N04401) Mechanical Properties

| Form and Condition | Tensile Strength | Yield Strength (0.2% Offset) | Elongation, % | Hardness |

|---|---|---|---|---|

| Annealed | 50 – 60 ksi 345 – 414 MPa | 30 – 40 ksi 207 – 276 MPa | 25 – 40 | Rockwell B 60 – 75 |

| Cold-Worked (Drawn) | 70 – 90 ksi 483 – 621 MPa | 40 – 60 ksi 276 – 414 MPa | 15 – 30 | Rockwell B 80 – 100 |

| Hot-Finished | 60 – 80 ksi 414 – 552 MPa | 30 – 50 ksi 207 – 345 MPa | 20 – 35 | Rockwell B 70 – 90 |

| Welded (As-welded, Annealed) | 45 – 65 ksi 310 – 448 MPa | 20 – 40 ksi 138 – 276 MPa | 20 – 30 | Rockwell B 55 – 80 |

| Stress-Relieved | 65 – 90 ksi 448 – 621 MPa | 35 – 55 ksi 241 – 379 MPa | 25 – 35 | Rockwell B 75 – 95 |

Monel 401 Introduction

Overview

As a trusted Monel 401 alloy supplier, Huaxiao Metal is at the forefront of providing high-quality, budget-friendly solutions for an extensive array of industrial applications. Monel 401 (UNS N04401), a highly regarded nickel-copper alloy, has gained significant acclaim for its distinctive properties. Its exceptional corrosion resistance, especially in reducing environments, sets it apart. This makes it an ideal choice for industries like specialty chemical manufacturing, pharmaceutical R&D, and electronics production, where the understanding of monel composition, specifically the Monel 401 chemical composition, is crucial for ensuring reliable performance. When contrasted with alloys such as 401 stainless steel or even other Monel variants, Monel 401 showcases unique behavior. For instance, while 401 stainless steel has its own set of ss 410 properties, Monel 401 excels in withstanding corrosive chemicals and gases due to its particular alloy 401 makeup, which consists mainly of nickel as the base element, along with copper and trace amounts of other alloying elements like iron, manganese, and carbon. This monel metal composition gives it an edge in applications where material integrity in the face of harsh chemicals is non-negotiable.

Mechanical Properties

Monel 401 is known for its robust mechanical capabilities that enable it to perform consistently in high-stress situations across a broad temperature spectrum.

- Tensile Strength: Up to 60 ksi (414 MPa)

- Yield Strength (0.2% Offset): 30 – 40 ksi (207 – 276 MPa)

- Elongation: 25 – 40%

- Hardness: Rockwell B 60 – 75

These properties, combined with its relatively stable mechanical response under thermal fluctuations, empower 401 alloy Monel to operate dependably where mechanical stress and changing temperatures are common. Understanding the monel composition is key here, as it directly influences these mechanical properties.

Corrosion Resistance

The corrosion resistance of Monel 401 is truly remarkable. It thrives in reducing environments, safeguarding equipment from the erosive effects of aggressive chemicals.

- Reducing Environment Resistance: Monel 401 forms a tenacious passive layer when exposed to reducing agents, effectively warding off corrosion. This is vital in chemical plants dealing with sulfurous compounds, for example, where the composition of monel metal plays a huge role in its protection mechanism.

- Acid Resistance: It demonstrates excellent resistance to certain acids, protecting vital components in acidic processes such as those in pharmaceutical manufacturing. The unique alloy 401 formulation is responsible for this enhanced acid resistance.

- Gas Resistance: Facing reactive gases, Monel 401 maintains its structural integrity. In electronics applications, this property is invaluable, as it shields sensitive components from gas-induced degradation, a feat made possible by its carefully balanced monel composition.

Density of Monel 401

At room temperature, the density of Monel 401 is around 8.88 g/cm³ (8880 kg/m³). This density contributes to its overall strength and durability, allowing it to endure the rigors of industrial operations. It’s another aspect influenced by the alloy’s chemical makeup, highlighting the importance of the Monel 401 chemical composition.

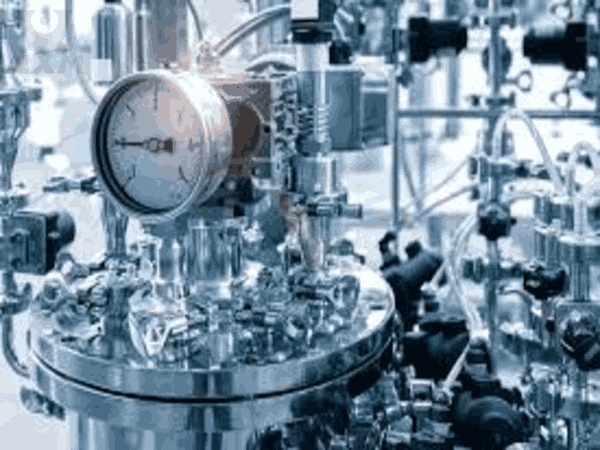

Typical Applications

- Specialty Chemical Manufacturing: Here, Monel 401 is used to fabricate reaction vessels, heat exchangers, and piping systems. The harsh chemicals involved demand an alloy with superior corrosion resistance, and Monel 401, with its known monel composition, fits the bill perfectly.

- Pharmaceutical Production: Components like valves, condensers, and storage tanks benefit from Monel 401’s corrosion resistance and biocompatibility. Its ability to resist chemical degradation, rooted in its alloy 401 structure, ensures product purity.

- Electronics: Electrical contacts, shielding enclosures, and connectors made of Monel 401 are protected from corrosion and electromagnetic interference. The specific monel metal composition enables these parts to function optimally in the presence of potentially corrosive substances.

As a wholesale Monel 401 supplier, Huaxiao Metal offers a wide selection of Monel 401 products, covering bars, sheets, tubes, and coils. Our offerings come in standard sizes, and we also accommodate custom orders to match the precise requirements of our customers. Whether you’re involved in large-scale industrial projects or small, specialized applications, our strict quality control procedures ensure that every product leaving our facility meets the highest standards. Contact us right away to discover more about Monel 401 pricing, availability, and how we can meet your unique needs.

Monel 401 Applications

Marine Industry

Pharmaceutical Manufacturing

Nuclear Power Industry

Marine and Offshore Applications

FAQ

What is the composition of Monel metal?

Monel metal is mainly a nickel-copper alloy. For example, Monel 400 typically contains 63.0 – 70.0% nickel, 28.0 – 34.0% copper, along with small amounts of other elements like 2.5 – 3.5% iron, up to 2.0% manganese, and trace amounts of carbon, silicon, sulfur, and phosphorus. The composition varies among different Monel grades, such as Monel 401, which has its own specific proportion of alloying elements to achieve distinct properties.

More Monel Grades

Monel Alloy 400

January 2, 2025

No Comments

Previous slide Next slide Monel Alloy 400 Shapes: Plate & Sheet, Coil, Strip, Bar, Pipe & Tube, Wire & Mesh Grades: ASTM: B127 / UNS

Monel Alloy 404

December 18, 2024

No Comments

Previous slide Next slide Monel Alloy 404 Shapes: Plate & Sheet,Coil,Strip,Bar,Pipe & Tube,Wire & Mesh Grades: ASTM: B[Relevant ASTM grade number for 404] / UNS

Monel Alloy 401

December 18, 2024

No Comments

Previous slide Next slide Monel Alloy 401 Shapes: Plate & Sheet,Coil,Strip,Bar,Pipe & Tube,Wire & Mesh Grades: ASTM: [Relevant ASTM grade code for Monel 401] /