Incoloy Alloy 803

Shapes:

Plate & Sheet, Coil, Strip, Bar, Pipe & Tube, Wire & Mesh

Grades:

- ASTM: A240 / S80300

- JIS: G4304 / SUS803

- AISI: 803

- EN: 10088-2 / 1.4876

- Mill’s Standard: 803

Huaxiao Metal is a leading Incoloy Alloy 803 supplier, offering top-quality Incoloy 803 products with the best prices and services. We provide Incoloy 803, Incoloy 803H, and Incoloy 803HT in any specification, length, and thickness, ensuring each order undergoes strict quality inspection and careful packaging to meet customer requirements. Contact us now for your Incoloy alloy 803 needs!

Incoloy Alloy 803 Shapes

Incoloy 803 Plate & Sheet

Incoloy 803 alloys are highly valued for their outstanding resistance to oxidation, carburization, and excellent high-temperature strength. These properties make Incoloy Alloy 803 an ideal material for a wide range of industrial applications, especially in high-temperature environments. Below are the dimensions for Incoloy 803 Plates & Sheets:

Dimensions:

- Thickness: 0.3 mm – 200 mm

- Width: 40 mm – 600 mm, 1000 mm, 1219 mm, 1500 mm, 1800 mm, 2000 mm, 2500 mm, 3000 mm, 3500 mm, and other custom widths of Incoloy 803 available

- Length: 2000 mm, 2500 mm, 3000 mm, 5800 mm, 6000 mm, 12000 mm, and other custom lengths for Incoloy Alloy 803

For pricing, availability, and custom Incoloy 803 Plate & Sheet sizes, please contact us!

As a trusted Incoloy Alloy 803 supplier, Huaxiao Metals offers high-quality Incoloy 803 products. Whether you’re comparing Incoloy vs Inconel, looking for reliable Incoloy material solutions, or need custom Incoloy 803 specifications, we provide the best options tailored to your needs.

Incoloy 803 Coil

Incoloy 803 coils are highly regarded for their excellent resistance to oxidation and carburization at elevated temperatures. These coils offer exceptional strength and reliability, making them ideal for high-temperature industrial applications. Incoloy 803 is particularly effective in environments where heat and corrosive atmospheres are present. Below are the dimensions for Incoloy 803 Coils:

Dimensions:

- Thickness: 0.3 mm – 10 mm

- Width: 40 mm – 600 mm, 1000 mm, 1219 mm, 1500 mm, 1800 mm, 2000 mm, 2500 mm, 3000 mm, and other custom widths of Incoloy 803 available

- Length: Customizable, available in coils or specific lengths based on customer requirements

For pricing, availability, and custom Incoloy 803 coil sizes, feel free to contact us!

As a trusted Incoloy Alloy 803 supplier, we offer high-quality Incoloy 803 products tailored to your specific needs. Whether you need Incoloy 803 for aerospace, petrochemical, or industrial heating applications, we provide customized solutions for optimal performance.

Incoloy 803 Strip

Incoloy 803 strips are renowned for their excellent resistance to oxidation, carburization, and high-temperature strength, making them an ideal material for a variety of demanding industrial applications. These strips are especially effective in environments exposed to extreme heat and corrosive atmospheres. Below are the dimensions for Incoloy 803 Strips:

Dimensions:

- Thickness: 0.3 mm – 10 mm

- Width: 40 mm – 600 mm, 1000 mm, 1219 mm, 1500 mm, 1800 mm, 2000 mm, 2500 mm, 3000 mm, and other custom widths of Incoloy 803 available

- Length: Customizable, available in strips or specific lengths based on customer requirements

For pricing, availability, and custom Incoloy 803 strip sizes, feel free to contact us!

As a reliable Incoloy Alloy 803 supplier, we provide high-quality Incoloy 803 strips suited for a wide range of applications, including heat exchangers, furnace components, and petrochemical reactors. We offer customized solutions to meet your specific needs in high-temperature environments.

Incoloy 803 Pipe & Tube

Incoloy 803 pipes and tubes are highly valued for their exceptional resistance to oxidation, carburization, and high-temperature corrosion, making them ideal for use in high-temperature, high-stress environments. These pipes and tubes are commonly used in applications such as heat exchangers, gas turbines, and chemical processing, where both strength and durability at elevated temperatures are critical. Below are the dimensions for Incoloy 803 Pipe & Tube:

Dimensions:

- Thickness: 0.3 mm – 50 mm

- Outer Diameter: 10 mm – 500 mm, 1000 mm, and other custom diameters of Incoloy 803 available

- Length: Customizable, available in standard lengths or specific customer requirements

For pricing, availability, and custom Incoloy 803 pipe & tube sizes, please feel free to contact us!

As a trusted Incoloy Alloy 803 supplier, we offer high-quality Incoloy 803 pipes and tubes designed to perform in extreme environments. Whether used in power generation, aerospace, or petrochemical applications, our products are tailored to meet your specific needs, ensuring reliable performance in high-temperature and corrosive conditions.

Incoloy 803 Wire & Mesh

Incoloy 803 wire and mesh are known for their exceptional resistance to oxidation, carburization, and high-temperature strength, making them ideal for applications in environments that experience high heat and corrosive conditions. These materials are widely used in industrial heating, furnace components, filtration systems, and other high-performance applications. Below are the dimensions for Incoloy 803 Wire & Mesh:

Dimensions:

- Wire Diameter: 0.1 mm – 5 mm

- Mesh Size: Customizable, typically ranging from 0.5 mm to 50 mm openings

- Width: 40 mm – 1000 mm, and other custom widths of Incoloy 803 wire mesh available

- Length: Customizable, available in rolls or specific lengths based on customer requirements

For pricing, availability, and custom Incoloy 803 wire & mesh sizes, please feel free to contact us!

As a leading Incoloy Alloy 803 supplier, we provide high-quality Incoloy 803 wire and mesh designed to meet the specific needs of high-temperature and corrosive applications. Whether you need materials for filtration, heat exchangers, or furnace components, our custom solutions ensure optimal performance and durability.

Incoloy 803 Bar

Incoloy 803 bars are highly valued for their superior resistance to oxidation, carburization, and excellent high-temperature strength. These bars are ideal for applications where high thermal stability and resistance to extreme heat are required, such as in gas turbines, furnace components, and petrochemical processing. Below are the dimensions for Incoloy 803 Bars:

Dimensions:

- Diameter: 10 mm – 500 mm, and other custom diameters of Incoloy 803 available

- Length: Customizable, available in standard lengths or specific customer requirements

For pricing, availability, and custom Incoloy 803 bar sizes, please feel free to contact us!

As a trusted Incoloy Alloy 803 supplier, we provide high-quality Incoloy 803 bars designed to meet the rigorous demands of high-temperature and corrosive environments. Whether for aerospace, power generation, or industrial applications, we offer tailored solutions to meet your specific needs.

Incoloy Alloy 803 Chemical Composition

Incoloy® 803 (UNS N08803) is a high-performance nickel-iron-chromium alloy known for its outstanding resistance to oxidation, carburization, and exceptional high-temperature strength. This makes Incoloy Alloy 803 an ideal material for industrial applications, particularly in high-heat environments like gas turbines, heat exchangers, and furnace components. Below is the typical chemical composition of Incoloy 803:

| Element | Composition (wt.%) |

|---|---|

| Nickel (Ni) | 29.0 – 34.0 |

| Iron (Fe) | Balance (approximately) |

| Chromium (Cr) | 19.0 – 23.0 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 1.50 |

| Silicon (Si) | ≤ 1.00 |

| Sulfur (S) | ≤ 0.015 |

| Copper (Cu) | ≤ 0.75 |

| Aluminum (Al) | ≤ 1.00 |

| Titanium (Ti) | 0.15 – 0.60 |

| Phosphorus (P) | ≤ 0.015 |

Data Sheet

Physical Properties

Incoloy® 803 (UNS N08803) Properties

| Property | Value |

|---|---|

| Density | 8.10 g/cm³ |

| 0.292 lb/in³ | |

| Melting Range | 2460 – 2550 °F |

| 1350 – 1400 °C | |

| Modulus of Elasticity | |

| Tension | 28.0 x 10³ ksi |

| Compression | 28.0 x 10³ ksi |

| Torsion | 10.0 x 10³ ksi |

| Poisson’s Ratio | 0.31 |

| Curie Temperature | 660 – 800 °F |

| 350 – 425 °C |

Mechanical Properties

Incoloy® 803 (UNS N08803) Mechanical Properties

| Form and Condition | Tensile Strength | Yield Strength (0.2% Offset) | Elongation, % | Hardness |

|---|---|---|---|---|

| Annealed (Solution Annealed) | 70-100 ksi | 30-60 ksi | 30-60 | Brinell (3000-kg): 207-414 |

| 483-690 MPa | 207-414 MPa | |||

| Cold-Worked (Drawn) | 100-130 ksi | 35-55 ksi | 25-50 | Brinell (3000-kg): 241-448 |

| 690-896 MPa | 241-379 MPa | |||

| Hot-Finished | 85-110 ksi | 35-60 ksi | 30-55 | Brinell (3000-kg): 207-414 |

| 586-758 MPa | 241-414 MPa | |||

| Welded (As-welded, Annealed) | 70-90 ksi | 30-50 ksi | 20-45 | Brinell (3000-kg): 175-310 |

| 483-621 MPa | 207-345 MPa | |||

| Heat-Exchanger Tubing (Annealed) | 75-100 ksi | 30-55 ksi | 25-50 | Brinell (3000-kg): 193-379 |

| 517-690 MPa | 207-379 MPa | |||

| Stress-Relieved | 85-115 ksi | 40-70 ksi | 30-55 | Brinell (3000-kg): 241-448 |

| 586-793 MPa | 241-448 MPa |

These mechanical properties make Incoloy® 803 an ideal material for high-temperature and

Incoloy 803 Introduction

Overview

As a leading Incoloy Alloy 803 supplier, Oios Metals offers cost-effective and high-performance Incoloy® 803 products for a variety of industrial applications. Incoloy® 803 (UNS N08803) is a nickel-iron-chromium alloy renowned for its exceptional resistance to oxidation and carburization at elevated temperatures. This alloy combines the high-temperature strength of austenitic alloys with excellent resistance to oxidation, sulfidation, and carburization, making it ideal for demanding applications in petrochemical, chemical processing, and power generation industries.

When considering Incoloy vs Inconel, Incoloy 803 stands out due to its superior corrosion resistance and mechanical strength at high temperatures, especially in environments that involve aggressive chemicals or high heat. While Inconel is more commonly used for extreme high-temperature conditions, Incoloy 803 provides excellent performance in slightly lower but still elevated heat environments. For a more cost-effective solution where oxidation resistance and creep strength are key, Incoloy material like Incoloy 803 is often preferred.

Mechanical Properties

Incoloy 803 offers outstanding mechanical properties at high temperatures, which makes it an ideal choice for applications exposed to both mechanical stress and elevated temperatures. The alloy maintains tensile strength and creep resistance up to approximately 1100°F (593°C).

- Incoloy 803 retains its mechanical properties, even under extreme heat, ensuring long-term performance in demanding environments.

- It offers excellent resistance to thermal fatigue, which is crucial in industries like aerospace, power generation, and petrochemical refining.

- Incoloy 803 has low thermal expansion, which helps reduce stress on components in high-temperature environments.

Corrosion Resistance

Incoloy 803 demonstrates excellent corrosion resistance to oxidation, carburization, and sulfidation, making it ideal for high-temperature applications in aggressive chemical environments. This is particularly important in furnace components, combustion chambers, and gas turbines.

- Oxidation Resistance: Incoloy 803 provides outstanding protection against oxidation at elevated temperatures, ensuring reliability in thermal processing applications.

- Corrosion Resistance: The alloy excels in environments exposed to sulfur-containing gases and acids, making it ideal for chemical processing, petrochemical, and refining industries.

- It also has resistance to chloride stress corrosion cracking, which further enhances its durability in high-temperature and corrosive atmospheres.

Density of Incoloy 803

The density of Incoloy 803 is approximately 8.10 g/cm³ (8100 kg/m³) at room temperature, which provides excellent strength and durability in high-temperature environments.

Typical Applications

- Heat exchangers and furnace components in chemical and petrochemical industries

- Nuclear reactors and reactor components

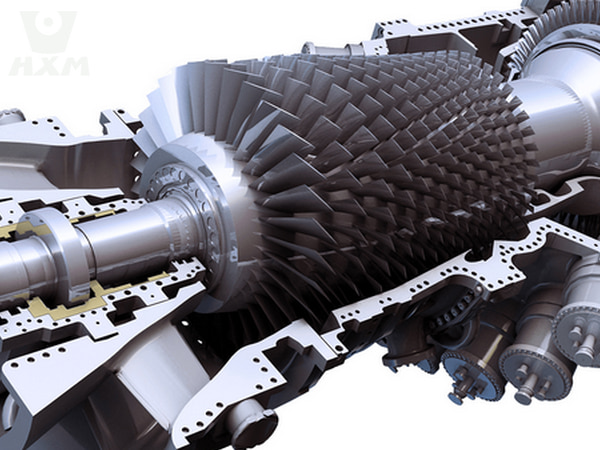

- Industrial gas turbines and combustion chambers

- Piping and furnace tubes exposed to high temperatures

- Heat treatment and thermal processing equipment

- Boilers and superheaters in power plants

- Chemical processing systems operating at elevated temperatures

Incoloy 803, Incoloy 803H, and Incoloy 803HT are selected for their excellent ability to withstand extreme conditions, ensuring long-term reliability and performance in a wide range of high-temperature environments. These alloys are ideal for use in petrochemical refining, nuclear and aerospace applications, and thermal processing equipment where strength, corrosion resistance, and oxidation resistance are essential.

Incoloy Alloy 803 Supplier

As a trusted Incoloy Alloy 803 supplier, Oios Metals offers Incoloy Alloy 803 products that meet the most stringent industry standards. Whether you are looking for Incoloy 803 for heat exchangers, gas turbines, furnace components, or chemical processing systems, we supply Incoloy 803 in various shapes and sizes, including plates, sheets, bars, coils, and tubes.

We also offer competitive pricing, expert guidance, and customized solutions for your Incoloy Alloy 803 requirements. If you need more information on Incoloy material, Incoloy 803 chemical composition, or Incoloy 803 welding procedures, please contact us today for professional assistance.

Keywords: Incoloy 803, Incoloy Alloy 803, Incoloy Alloy 803 Supplier, Incoloy 803 Material, Incoloy Element, Incoloy vs Inconel, Incoloy 803 Chemical Composition, Incoloy 803 Applications, Incoloy 803 Properties, Incoloy 803 Supplier, Petrochemical Equipment, Heat Exchangers, Gas Turbines, High-Temperature Alloys, Industrial Alloys, Corrosion-Resistant Alloys, Welding Incoloy 803.

Incoloy 803 Applications

Furnace Components

Gas Turbine Components

Petrochemical and Chemical Processing

Aerospace Applications

FAQ

What are the properties of INCOLOY 803?

More Incoloy Grades

Incoloy Alloy 825

Previous slide Next slide Incoloy 825 Alloy Shapes: Plate & Sheet, Coil, Strip, Bar, Pipe & Tube, Wire & Mesh Grades: ASTM: B424 / UNS

Incoloy Alloy 803

Previous slide Next slide Incoloy Alloy 803 Shapes: Plate & Sheet, Coil, Strip, Bar, Pipe & Tube, Wire & Mesh Grades: ASTM: A240 / S80300

Incoloy Alloy 800

Previous slide Next slide Incoloy Alloy 800 Shapes: Plate & Sheet,Coil,Strip,Bar,Pipe & Tube,Wire & Mesh Grades: ASTM: A240 / S80000, S800H, S800HTJIS: G4304 / SUS800,